Week 268 - 2 January 2008

Tonight our thought was to chose a simple task, then complete it. Haa

We have always said the top gun turret would rotate. So lets get-er-done! First job is to modify a servo to run continuous. Since I have a lot of Airtronics 94102 servos laying around, we used one of them. The Mod was really quite simple. Simply remove the gear train and cut of the stops as shown on our instructions and put back together. It worked perfectly.

We mounted the turret directly to the servo cross arm, then strategically tried to mount the servo. First time we had some brain gas, so we broke the mount out and tried again. There that’s better.

The cutout is too small and needs expanded some. But at the sides the cutout ends below the turret bottom. After much discussion we decided the probable solution to do is oversize the hole then add a sleeve/collar to the opening that would be flat at the top. We wanted to think about it some more before we doing it, so we called it a night. Hopefully next week we can finish this simple job.

The top turret is done and works very cool.

After thinking about it all week we agreed our collar scheme was probably the best to do. During the week I also realized the current location of the turret was a tad low. (For you layman/laywomen a tad = approx ¼ of an inch). We choose 1/32 aircraft plywood to make the collar from and cut it 1” high. After several fittings the collar was holding a nice round shape. So we notched the collar for the fuse bulkhead and servo mounting rails. Every thing was looking fairly well but it needed one more minor adjustment. Well when that person removed the collar he broke it. Under the policy of you broke it, you make the replacement, the guilty party proceeded to make the new collar. When Greg was done with this chore I started to install the collar and broke the new one. How does Mr Murphy keep getting in this house? After I got the new part made, (again) we got just a tad smarter and soaked the collar with ammonia water and very, very carefully installed the collar. What a great fit! Glue that thing in place before something else happens.

To raise the turret we simply glued ¼” balsa on top of the existing base and painted it black. Back to the collar, it needed just a wee bit of filler for that perfect look. Now we primed the area and let dry. Re-sand the area and paint the inside area olive drab and a 2nd coat of primer on the outside. Let that dry just a little then hook up the servo tester and make the turret move. Works perfect, spin left as much as you want then turn to the right as far as you want. Also as fast or slow as you want……..WAY COOL……

We now all have big smiles on our faces, so decide to call it a night again as one of the group members have a meeting they must attend.

Thanks for stopping by!

Week 272 - 30 January 2008

Well, I guess I owe everyone an apology. Last week Greg called and was sick as a dog, so we called the night off. Instead of filing the report like I should have, I threw together a new foamy to fly indoors on the following night…….So SORRY!

We did work tonight. The outboard wing section access panels and ailerons had not been refitted since everything was fiber glassed. We started off refitting the access panels first. The screw holes needed re-drilled and the panels needed sanded to fit and re-primmed. Next we started to hook up the ailerons. After a long search we finally found the mounting screws. At this point we realized we didn’t have any of the 2mm aircraft nuts which we wanted to use on the linkages. So that has to be put on hold till we get some ordered in or picked up.

We went ahead and started to mount the aileron hinges with the servo screws and found the wood was stripped a few places. To fix this out we drilled the holes larger to accept ¼” long pieces of inner ny-rod. This is an old trick which works well. You are making plastic threads plus as the screw is inserted, the tubing expands to a tight locked fit

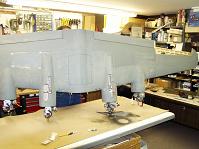

Through out the night we were priming and painting bare wood as necessary. The elevators and rudder were looking a little lonely lying on the table all by themselves so we put them on the aircraft for a different look. We must have forgotten to sand off the bottom of the rudder. It drags on the tail gunner’s roof and will need to be addressed latter. Once again we called an early night.

Week 275 - 19 February 2008

Well once again I must start off the report with an apology. Week 273 Greg could not make our new Tuesday build night and selfishly I would not work Wednesday night as I wanted to fly indoors. Then Week 274 rolls around and I am sick as a dog with severe sinus infection and called the night off again. (Seems to be too common….sorry).

We started the night with Greg assembling the ailerons and access doors on both wings. Rick and myself mocked up an exhaust stack which now needs to be welded together. The pictures were taken after the guys left, there fore you can not see the angle bracket which will go back to the motor mount and secure/support the exhaust.

Next all three of us turned to the bomb bay doors. After much discussion it was left up to me to do some mechanical layouts of the good ole computer to prove/disprove a couple of our ideas.

Lastly we turned to the cowls. Our cowls are actually 2 pieces. One is the actual cowl and the second is really a nacelle extension because our large gas motors are set too far reward. We have 1 extra set of cowls both inner and outer. So se did some rough fitting of the inner cowl before calling it a night. Next build night will probably start with us starting to glass the cowls.

Week 276 - 26 February 2008

We got just a little of a late start as I had a Dr. Appointment, and it went long like they always seem too.

Rick got our sample exhaust stack welded and it looks great. We had no problem mounting, beyond having to add a few spacer washers. Anyhow it works great.

Next we put our first fiberglass coat on the 8 nacelle/cowl pieces. Once this was done we had stunk up the basement so we called it a night.

Side note, next week build night will be on Wednesday due to Mr. Golden’s request.

Week 277 5 March 2008

Tonight not much got accomplished. The epoxy we used for the fiber glassing last week was not cured yet. I talked to our contact during the week about this. Jeff thought if we baked/heated the parts they would dry. A little time with the heat gun showed no significant change. We made the decision to use an un-opened batch of epoxy and try it again, as we have nothing to lose at this point. When starting to mix the epoxy I figured out that last week we/I probably mixed the epoxy backwards. The stuff we are using mixes at a 3 to 1 rate. We mixed a small test batch correctly and sat around talking watching epoxy dry. We now decided to get back with Jeff and recheck our options before we go further. This epoxy takes 24 hours to cure and we wanted to make sure everything is correct. We sure don’t want to make back to back mistakes.

Greg had picked up more aluminum pipe for the exhaust. We cut into sections for the welder to weld the first step of the exhaust assembly.

I had a medical procedure last week and am still a little run down, so I welcomed the early quit time tonight. Sorry for the lack of pictures tonight, just nothing to take pictures of.

Week 279 18 March 2008

Well here I go again! Last week Greg was on vacation with his wife. Rick and I had decided to work anyway, but Ricks wife had to work late. Therefore, Rick had to take up the responsibility of being Dance Dad.

Today at work I realized that we had not yet re-chartered our flying club with AMA this year. (Rick and I are both club officers) We are about out of time, so while Greg worked on the plane, Rick and I did the paperwork for the club.

What Greg got accomplished, was putting on the 2nd coat of fiberglass on our cowls and nacelle extensions. Since this is boring and not changing anything visually, we did not take pictures again tonight. Sorry!

Hope everyone is sitting down, as we did work on the project tonight.

The bad news is sometimes in life we just have to back up and start all over again. Well that is what is happing to our nacelle extensions and engine cowls. As you recall, we (I) mixed the first batch of epoxy wrong, and it never dried. Then we did the second coat and thought it might heal our sins. WRONG………We initially started of sand and eliminate the cloth bubbles when we realized the first coat was not attached to the plastic. So we slammed on the brakes, and after a brief discussion, started to strip off all the glass work to this point. This was a big chore then the plastic was cleaned with alcohol in preparation to re-use our plastic molds.

We also epoxied a donut looking ring to the inside of the nacelle extensions. This is in preparation for the future engine cowl mounting blocks. Once this was done we were a little low and called it a night.

The spring like Warmth and Sunshine made us not too excited to sit indoors and work on the project.

So Guess what????????????

We didn’t work on it……………….Surprised????????????

Instead we enjoyed a boy’s night out

Oh well, may be next week.

Well once again we didn’t work the last couple of weeks. We have our excuses but I am sure you are tired of hearing them!

Since we messed up the cowls and nacelle extensions the first time, we are doing things differently this time. We cut out the center openings of both the nacelle extensions and the cowls. After the cutouts were made and sanded, we realized the forms were still quite unclean and nasty. So we got out the sandpaper and alcohol (to wash the parts in…..not to drink) and proceeded to work. This took most of the night, so here we stand.

I guess there are several lessons to be learned here.

Do it right the first time. (make sure you know the proper epoxy mix)

Don’t continue so long until you decide to properly correct the mistake.

Any how, the forms are not really spotlessly clean. Next meeting will start the glassing process again! (Notice I did not say next week (you just never know about us)).

The weather is getting nice again, so go fly until next time.

We did work again tonight, at least 2 of us showed up. Seems Greg was AWOL, however he did call in, using lots of 4 letter words (WORK). I told him not to use that kind of language over my phone. Hahaha

Rick and I did glass the first coat (layer) of fiberglass over the nacelle extensions and the cowls.

We did not take any pictures tonight….Sorry!

Week 287 14 May 2008

Well as you have guessed by now we did not work last week.

We were back on target and worked tonight. No pictures however, I just didn’t see the need to show pictures of the same thing week after week. We sanded the nacelle extensions and cowls then applied layer 3 of glass cloth.

Our buddy Dale Beck came down and chewed the fat with us tonight. He reinforced our thinking on the glassing of the cowls. He also gave us different slant/ideas on our carb linkage problem. After that we said our good bye’s and parted ways for yet another week.

If you want to be part of the Day Dream Believer Project, PayPal donations are graciously accepted.